Sustainability Report

Reynders label printing

2024

Consolidated Sustainability Report

according to ESRS standards

ESRS 2 | General Disclosures

Business Profile & Sustainability Governance4BP-1 General basis for preparation4BP-2 Disclosures in specific circumstances5GOV-1 Role of administrative bodies6GOV-2 Governance of sustainability7GOV-3 Incentive schemes8GOV-4 Due diligence9GOV-5 Risk management10SBM Strategy and business model11IRO Impact and risk assessments12ENVIRONMENTAL

E1 | Climate change13E1-1 Transition plan13E1-2 Policies13E1-3 Actions and resources13E1-4 Targets13E1-5 Energy consumption and mix13E1-6 Greenhouse gas emissions13E2 | Pollution14E2-1 Policies14E2-2 Actions and resources14E2-3 Targets14E5 | Resource use and circular economy15E5-1 Policies15E5-2 Actions and resources15E5-3 Targets15E5-4 Incoming resource flows15E5-5 Outgoing resource flows15SOCIAL

S1 | Own workforce16S1-1 Policies16S1-2 Engagement processes16S1-3 Redress processes16S1-4 Actions and resources16S1-5 Targets16S1-6 Employee demographics16S1-7 Non-employees16S1-8 Collective bargaining coverage16S1-9 Diversity16S1-10 Living wages16S1-11 Social protection16S1-12 Persons with disabilities16S1-13 Training and development16S1-14 Health and safety16S1-15 Work-life balance16S1-16 Remuneration16S1-17 Incidents and grievances16S2 | Workers in the value chain17S2-1 Policies17S2-4 Actions and resources17S4 | Consumers and end users18S4-1 Policies18Corporate Social Responsibility19Foreword

Our Mission and Vision

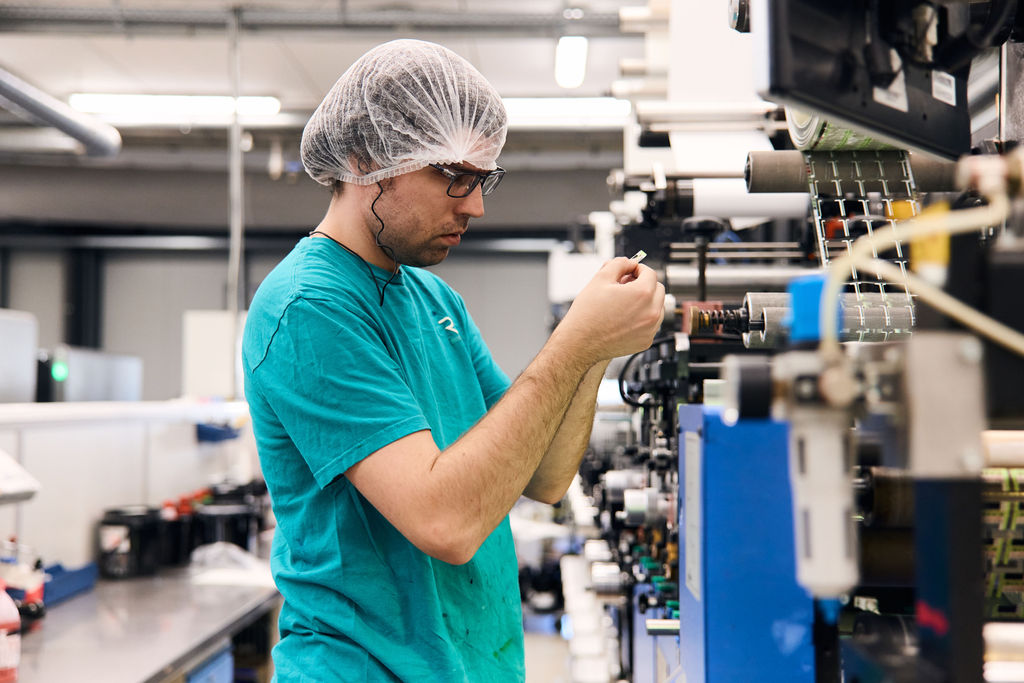

At Reynders, our vision has always extended beyond mere expansion. Label printing is the backbone of numerous industries—when businesses grow, so do we, and when challenges arise, we stand together with our partners to find solutions. The demand for modern, environmentally responsible label solutions continues to rise, and we are proud to meet this demand with cutting-edge, sustainable solutions that set new standards in our industry.

Our commitment to high-quality products, integrating technology, and maintaining the highest sustainability certifications underscores our dedication to progress that benefits both businesses and communities. We take great pride in enabling companies to expand, innovate, and create jobs, knowing that our products support industries that drive economic growth.

Social Responsibility

Despite the challenges of our time, we continue to move forward with confidence, proving that long-term vision and responsible investment are key to success. None of this would be possible without the dedication of our team, the trust of our investors, and the strong partnerships we have built over the years.

- •Modern Label Production: We are creating a European portfolio of modern, environmentally friendly label production facilities with high-quality printing technologies

- •Sustainability: We appreciate our investors' assets and contribute to the sustainable future of the label industry in Europe

- •Communities: We are a responsible member of society, especially in the communities where we operate

- •Employees: We provide an inspiring environment for our employees and support their development

We draw on tradition and redefine it, enabling us to create new business opportunities and make these regions a better place to live.

Key Figures for 2024:

- Total Revenue: 71,687,273.65 EUR

- Total Asset Value: 120,332,329 EUR

- Number of Employees: 692

- Scope: Belgium, France, Poland, Germany, Spain, India

This report presents a comprehensive view of our activities in the areas of environmental responsibility, social responsibility, and corporate governance (ESG). We transparently present our results, challenges, and plans for the future.

Our Environmental Impact

We are committed to reducing our environmental footprint through sustainable practices, energy efficiency, and responsible resource management across all our operations.

E1-1 | Transition plan for climate change mitigation

Decarbonisation Plan

Reynders label printing has established a structured decarbonisation plan that targets emission reductions across Scopes 1, 2 and 3, aligned with its CDP-disclosed climate commitments and verified under the GHG Protocol Corporate Standard. The plan focuses on lowering direct energy-related emissions, improving energy efficiency, and expanding renewable energy capacity.

Emission Reduction Targets

Key Measures and Actions

Energy Efficiency and Building Improvements

- ✓Ongoing LEDification across all sites, including replacement of remaining fluorescent and halogen lighting.

- ✓Installation of heat exchangers, roof insulation, and low-energy UV curing systems to reduce thermal losses and power demand.

- ✓Motion detectors installed in several offices and production rooms to control lighting and limit unnecessary energy use.

- ✓Gradual replacement of fossil-fuel-based heating systems with high-efficiency alternatives.

Renewable Energy

- ✓Deployment of photovoltaic solar panels at sites in Spain and Poland, contributing 3.76% of total electricity consumption in 2024 (up from 1.43% in 2023).

- ✓Evaluation of additional solar capacity across other European sites by 2026.

Fleet Electrification

- ✓Full electrification of the company's car fleet, eliminating direct fuel combustion emissions and significantly reducing Scope 1 emissions.

Water Efficiency

- ✓Installation of rainwater collection systems at new and expanded building sections.

- ✓Awareness-raising campaigns across the Group to promote responsible water usage and reduction of consumption in production and sanitary areas.

Scope 3 Management

- ✓Collaboration with suppliers to reduce the carbon footprint of raw materials, particularly paper, films, and inks.

- ✓Implementation of the Triple R Program (Reduce – Reuse – Recycle) to minimise material intensity and waste.

Monitoring and Verification

- ✓Emission data tracked per m² of production and verified under ISO 14064.

- ✓Continuous improvement monitored through CDP reporting and ISO 14001 management reviews at certified sites.

Through on-site renewable generation, energy and water efficiency upgrades, full fleet electrification, and supplier collaboration, Reynders expects to achieve or exceed all near-term reduction targets by 2027, maintaining continuous improvement toward its 2030 decarbonisation goal.

Paris Agreement Alignment

Reynders label printing's greenhouse gas (GHG) reduction targets are aligned with the 1.5°C global warming limit of the Paris Agreement, as they reflect the decarbonisation trajectory compatible with science-based targets for the printing and packaging sector.

Integration with Business Strategy

Reynders label printing integrates its climate action plan directly into its corporate and financial strategy. Investments in solar panels, LED curing, and energy-efficiency technologies are part of the annual CAPEX plan, supporting both cost reduction and emission goals. Progress on CO₂ reduction and renewable energy use is reviewed annually by management and the Board.

Unavoidable Emissions Management

Despite ongoing progress, Reynders label printing recognises that certain process-related and energy-intensive emissions remain unavoidable due to the thermal drying and curing stages inherent to label printing and material processing. Such residual emissions could slow down progress toward absolute zero in the short term, especially at sites still partly dependent on natural gas for heat generation and where production scale limits the feasibility of full electrification.

E1-2 | Policies related to climate change mitigation and adaptation

Disclosure of reasons for not having adopted policies

Reynders label printing has not yet adopted a stand-alone Climate Change Policy. However, the company manages climate-related issues effectively through existing management systems, verified methodologies, and group-wide environmental commitments.

Greenhouse gas emissions are monitored and reported in accordance with ISO 14064, covering Scope 1, 2 and 3 emissions across all sites. Several production facilities are additionally certified under ISO 14001 Environmental Management System, while all operate under a group-wide ISO 9001 Quality Management System that embeds procedures for energy efficiency, process optimisation and continuous improvement.

Reynders also aligns with international frameworks such as REACH, FSC certification, and the Ethical Trading Initiative (ETI) Base Code, supporting environmentally and socially responsible practices throughout the supply chain.

Although a formal Climate Change Policy has not yet been introduced, these systems and standards collectively ensure a structured and proactive approach to climate management, effectively fulfilling the intent of such a policy. Reynders intends to formalise a concise Climate Change Policy in the near future to ensure full alignment with ESRS E1 requirements and to consolidate its existing commitments under a single framework.

E1-3 | Actions and resources in relation to climate change policies

Climate Mitigation Measures

We implement climate mitigation measures, including decarbonisation and nature-based solutions.

Resource Requirements

The action plan does not require significant expenditures beyond planned operational and capital investments.

E1-4 | Targets related to climate change mitigation and adaptation

Reynders has set comprehensive targets to reduce greenhouse gas emissions across all scopes. The following table presents our base year values, progress in 2023 and 2024, and the pathway toward our 2025-2030 reduction commitments.

| Target | Base Year | Base Value | 2023 Value | 2023 Progress | 2024 Value | 2024 Progress |

|---|---|---|---|---|---|---|

| Scope 3 CO₂e/m²; 25% decrease in 2027 vs 2022 | 2022 | 0.000183477 | 0.000139131 | -24.17% | 0.00003402 | -81.46% |

| Scope 1+2 (location based) CO₂e/m²; 15% decrease in 2025 vs 2018 | 2018 | 0.000120089 | 0.000081549 | -32.09% | 0.00011612 | -3.30% |

| Scope 1+2 (location based)+3 CO₂e/m²; 15% decrease in 2025 vs 2013 | 2013 | 0.000365511 | 0.000220680 | 39.62% | 0.000150141 | -58.92% |

| Scope 3 CO₂e; 0.5% decrease in 2025 vs 2018 | 2018 | 10,444.02 | 7,955.75 | -23.82% | 1,913.52 | -81.68% |

| Scope 1+2 (location based); 30% decrease in 2030 vs 2018 | 2018 | 5,121.14 | 4,663.11 | -8.94% | 6,531.39 | 27.54% |

| Scope 1+2 Reynders Etiketten CO₂e/m²; 20% decrease in 2028 vs 2023 | 2023 | 0.00008812 | - | - | 0.00010754 | 22.04% |

| Scope 1+2 Reynders Pharmaceutical Labels CO₂e/m²; 20% decrease in 2028 vs 2023 | 2023 | 0.00010929 | - | - | 0.00014184 | 29.78% |

| Scope 1+2 Reynders Germany CO₂e/m²; 20% decrease in 2028 vs 2023 | 2023 | 0.00012296 | - | - | 0.00028723 | 133.60% |

Solar Energy Progress

2023 Solar Electricity Share

1,43%

2024 Solar Electricity Share

3,76%

E1-5 | Energy consumption and mix

| Energy Category | Value (MWh) | Share (%) |

|---|---|---|

| Fuel consumption from coal and coal products | - | - |

| Fuel consumption from crude oil and petroleum products | 99 | 0.53% |

| Fuel consumption from natural gas | 2 688 | 15% |

| Fuel consumption from other fossil sources | - | - |

| Purchased electricity, heat, steam, and cooling from fossil sources | 6 511 | 35% |

| Total fossil energy consumption | 9 298 | 50% |

| Consumption from nuclear sources | 2 938 | 16% |

| Fuel consumption for renewable sources (biomass) | - | - |

| Purchased electricity, heat, steam, cooling from renewable sources | 6 346 | 34% |

| Self-generated non-fuel renewable energy | - | - |

| Total renewable energy consumption | 6 346 | 34% |

| TOTAL ENERGY CONSUMPTION | 18 582 | 100% |

Renewable Energy Production

Self-generated renewable energy from solar panels

E1-6 | Gross Scopes 1, 2, 3 and Total GHG emissions

Scope 3 GHG Emissions Breakdown

| Category | Emissions (tCO₂eq) |

|---|---|

| 1. Purchased goods and services | 35 563 |

| 2. Capital goods | 1 739 |

| 3. Fuel and energy-related activities (not in Scope 1 or 2) | 2 241 |

| 4. Upstream transportation and distribution | 1 337 |

| 5. Waste generated in operations | 1 343 |

| 6. Business traveling | Included in cat. 1 |

| 7. Employee commuting | 549 |

| 8. Upstream leased assets | 76 |

| 9. Downstream transportation | 989 |

| 10-15. Other categories | Not applicable |

Methodologies and Emission Factors

Reynders label printing follows the GHG Protocol Corporate Standard for the calculation and measurement of greenhouse gas (GHG) emissions across Scopes 1, 2, and 3.

- Activity-based method: Uses specific operational data such as electricity consumption (kWh), fuel use (litres), or gas volume (GJ, m³)

- Spend-based method: Relies on financial data (EUR or USD) where activity data are unavailable

GHG Emissions Intensity (location-based)

GHG Emissions Intensity (market-based)

Significant Changes

There have been no significant changes in the structure of the business and in the value chain during the reporting period.

Primary Data Usage

Percentage of GHG Scope 3 calculated using primary data from suppliers or other partners in the value chain: 0.00%

Scope 3 Category Methodology

Categories Included (1, 2, 3, 4, 5, 7, 8, 9):

- •Category 1 (Purchased Goods and Services): Paper, plastic films, adhesives, inks, packaging materials. Calculated using spend-based method with CLIMATIQ and IPCC emission factors.

- •Category 2 (Capital Goods): New equipment, photovoltaic installations, production lines. Spend-based method with CLIMATIQ and IPCC factors.

- •Category 3 (Fuel and Energy-Related Activities): Extraction, production, and transport of fuels. DEFRA emission factors used.

- •Category 4 & 9 (Transportation): Upstream and downstream transport of materials and products. Spend-based approach with CLIMATIQ database.

- •Category 5 (Waste Generated): Based on internal waste records and ISPOP system. DEFRA emission factors applied.

Excluded Categories and Reasons:

- ○Category 6 (Business Travel): Currently included within Category 1. Will be separated in future reporting.

- ○Category 10-12 (Processing, Use, End-of-Life): Labels do not generate emissions during use or require processing. End-of-life responsibility lies with end users.

- ○Category 13-15 (Leased Assets, Franchises, Investments): Not applicable to business model.

E1-IRO-1 | Description of the processes to identify and assess material climate-related impacts, risks and opportunities

Process to Identify Climate-Related Impacts

Reynders label printing identifies and assesses climate-related impacts through a structured scenario-based analysis aligned with the IPCC's Shared Socioeconomic Pathways (SSP) and the GHG Protocol. The process evaluates potential physical impacts on company operations, supply chains, and GHG emissions under three global warming trajectories — SSP1-2.6 (low emissions), SSP3-7.0 (high emissions), and SSP5-8.5 (very high emissions).

Climate Risk Assessment Status

We have not identified material climate risks. However, we have assessed how sensitive our assets and activities are to identified climate risks.

The assessment considered temperature rise, heatwave frequency, precipitation variability, and drought patterns. All facilities are situated in low-to-moderate exposure zones (NUTS level 2 classification) with limited risk of flooding or extreme drought.

Transition Risks and Opportunities

We have not identified material risks and opportunities. However, we used climate-related scenario analysis to identify transition risks/opportunities and assess exposure.

Transition analysis used the SSP1-2.6 scenario, representing a 1.5°C pathway aligned with the Paris Agreement. Key opportunities arise from energy efficiency, renewable integration, and sustainable product innovation.

Climate Scenarios Used

SSP1-2.6

+1.6°C by 2100

Low-emission pathway reflecting strong global mitigation

SSP3-7.0

+4.0°C by 2100

High-emission scenario with regional adaptation challenges

SSP5-8.5

+4.4°C by 2100

Very high-emission trajectory with fossil-fuel-driven economy

Assets Compatibility

We have not identified assets or activities that are incompatible with the transition to a climate neutral economy or require significant efforts to be compatible with this transition.

E2-1 | Policies related to pollution

Disclosure of reasons for not having adopted policies

Reynders label printing has not yet adopted a standalone pollution prevention policy, as the company's approach to managing pollution-related aspects is already integrated within its broader environmental and quality management systems.

Pollution prevention, waste handling, and chemical management are covered through the implementation of ISO 9001, ISO 14064, and partially ISO 14001 standards, which define procedures for emissions control, solvent use, waste separation, and environmental monitoring at production sites.

Given that the company's operations generate only limited direct emissions and that chemical risks are strictly regulated under REACH, Reynders has prioritised compliance-based management and continuous monitoring over developing a separate formal policy. A dedicated pollution policy may be introduced in the future to consolidate existing practices.

E2-2 | Actions and resources related to pollution

SVHC Management System

Reynders label printing manages the presence of Substances of Very High Concern (SVHC) in its products through a structured REACH compliance system supported by supplier controls, internal documentation, and customer transparency.

Key Actions and Procedures:

- ✓Supplier Declaration and Monitoring: All suppliers are contractually required to confirm REACH registration and disclose the presence of SVHCs listed on the official ECHA Candidate List. Any material containing SVHCs above the 0.1% (w/w) threshold must be reported to Reynders without delay.

- ✓Internal Substance Register: Reynders maintains an internal SVHC register covering inks, adhesives, varnishes, and other raw materials used in production. This list is updated in line with new ECHA publications and is managed by the Group EHS and Quality teams.

- ✓Customer Communication: Whenever SVHCs are detected above regulatory thresholds, customers are informed transparently in compliance with REACH Article 33.

- ✓Preventive Material Selection: In cooperation with suppliers, Reynders promotes the use of low-migration inks, BPA-free coatings, and solvent-free adhesives to reduce chemical risks.

- ✓Awareness and Continuous Improvement: Technical and procurement teams receive regular REACH and SVHC training to ensure understanding of new regulatory developments.

E2-3 | Targets related to pollution

The company has not yet established measurable metrics or set specific targets for pollution-related material areas. However, the company monitors the effectiveness of its policies and actions regarding significant pollution impacts, risks, and opportunities even without formal measurable targets.

E2-5 | Substances of concern and substances of very high concern

Table lists Substances of Very High Concern (SVHC) reported by Reynders’ suppliers as present in materials used in production at concentrations above 0.1%:

| SVHC Substance | Material Code | Description |

|---|---|---|

| Dioctyl tin dilaurate (CAS 3648-18-8) | 340011 | PET 50 CLEAR GLOSS PFC 8K CRYOGENIC |

| 2-(Dimethylamino)-2-[(4-methylphenyl)methyl]-1-[4-(morpholin-4-yl)phenyl]butan-1-one (CAS 119344-86-4) | EXC540 | UV FLEXO INK: Yellow, Magenta, Cyan |

| 4,4'-Sulphonyldiphenol (BPS) (CAS 80-09-1) | 013335 | THERMAL ECO BPA FREE FSC S9500-BG40WH FSC |

| 4,4'-Sulphonyldiphenol (BPS) (CAS 80-09-1) | 013000 | THERMAL ECO BPA FREE FSC R5000N-BG40BR |

| 4,4'-Sulphonyldiphenol (BPS) (CAS 80-09-1) | 012998 | THERMAL ECO BPA FREE FSC S2000NG-BG40BR |

| Dicyclohexyl phthalate (DCHP) (CAS 84-61-7) | 012126 | TRANSFER PET36 TOP WHITE S8092-PET75 |

| 4,4'-Sulphonyldiphenol (BPS) (CAS 80-09-1) | 710047 | THERM G NO BPA FSC (907) 62Gpt PH515 |

| Diphenyl (2,4,6-Trimethylbenzoyl)phosphine Oxide (TPO) (CAS 75980-60-8) | 985UV1152 | UV WHITE G11 |

| Diphenyl (2,4,6-Trimethylbenzoyl)phosphine Oxide (TPO) (CAS 75980-60-8) | 985UV9166 | UV DEEP BLACK |

| 4,4'-Sulphonyldiphenol (BPS) (CAS 80-09-1) | 050080 | THERMAL ECO BPA FREE FSC / RP51 / HONEY GLASSINE 65-FSC |

| 4,4'-Sulphonyldiphenol (BPS) (CAS 80-09-1) | 050954 | TH ECO BPA FREE NXT+FSC / RH9X / HONEY GLASSINE 65-FSC |

| 4,4'-Sulphonyldiphenol (BPS) (CAS 80-09-1) | 052001 | THERMAL ECO BPA FREE FSC / RP45 / HONEY GLASSINE 65 |

| Bisphenol A (CAS 80-05-7) | 30060XU | ORANGE 35C THERMOCHROMIC UV CURING SCREEN |

| 2-Benzyl-2-dimethylamino-4-morpholinobutyrophenone (CAS 119313-12-1) | 80476GUF | PURPLE PMS 526 IR TO GREEN UV CURING FLEXO INK |

| 2-Benzyl-2-dimethylamino-4-morpholinobutyrophenone (CAS 119313-12-1) | 80502GUF | PANTONE PURPLE IR TO GREEN UV CURING FLEXO |

| 2-Benzyl-2-dimethylamino-4-morpholinobutyrophenone (CAS 119313-12-1) | 42318GUF | RED IR TO GREEN UV CURING FLEXO (PMS 485U) |

| 2-Benzyl-2-dimethylamino-4-morpholinobutyrophenone (CAS 119313-12-1) | 75927GUF | BLUE IR TO GREEN UV CURING FLEXO (PMS 485U) |

| 2-Benzyl-2-dimethylamino-4-morpholinobutyrophenone (CAS 119313-12-1) | 7CH37GUFB | BLUE IR TO GREEN UV CURING FLEXO (PMS 293) |

E2-IRO-1 | Description of the processes to identify and assess material pollution-related impacts, risks and opportunities

Materiality Assessment Results

The double materiality assessment concluded that pollution (ESRS E2) is not material from the financial perspective and only partially material from the impact perspective.

Material impact identified:

- •SVHC content in products – an actual negative impact related to the possible presence of substances of very high concern (e.g., DEHP, Boric Acid, BPA) in inks and adhesives used in label printing. This risk is managed through REACH compliance, supplier declarations, and customer notification if thresholds above 0.1% are exceeded.

Non-material impacts:

- ○Air pollution (VOCs): Emissions assessed as non-material due to limited solvent use and UV-curing technologies.

- ○Water pollution: No industrial water discharge occurs; operations are indoor-based.

- ○Soil pollution: No evidence of land contamination, spills, or leaks.

- ○Pollution of living beings and food resources: Managed under VOC and BkGS/IoP certification, ensuring low-migration inks and chemical safety for food contact.

- ○Microplastics: FSC-certified plastics used; no microplastic emissions reported.

E5-1 | Policies related to resource use and circular economy

Disclosure of reasons for not having adopted policies

Reynders label printing does not have a standalone internal policy specifically dedicated to resource use and circular economy. However, the company actively manages these topics through its ISO 14001-certified environmental management system, which provides a structured framework for resource efficiency, waste reduction, and continuous improvement across production sites.

Circular economy principles are integrated into day-to-day operations through the Triple R Program (Reduce–Reuse–Recycle), the use of FSC-certified and recyclable materials, supplier collaboration to optimise material thickness and reduce waste, and separation and monitoring of production waste streams under ISO 14064.

E5-2 | Actions and resources related to resource use and circular economy

Actions Taken

The company has taken measures to address impacts, manage risks, and seize opportunities regarding resource use and circular economy.

Resource Requirements

Implementing the action plan does not require significant expenditures beyond planned operational investments.

E5-3 | Targets related to resource use and circular economy

The company has not yet established measurable metrics or set specific targets for resource use and circular economy material areas. However, the company monitors the effectiveness of its resource and circular economy policies and actions even without formal measurable targets.

E5-4 | Resource inflows

Material Resource Inflows

Reynders' main material inputs consist of paper, plastic films (PP, PE), inks, and adhesives used in label printing. Based on internal estimates, approximately 80% of materials are used for product manufacturing and 20% for packaging. Resource consumption is tracked per 1,000 m² of production under the ISO 14001 environmental management system.

Data included from: Reynders label printing India, Reynders Spain, Reynders Etiketten Polska, Reynders Etiquettes France

Geographic Origin of Materials

Reynders prioritizes regional sourcing to minimize transport-related emissions and ensure supply chain resilience. The overwhelming majority of materials are sourced from European suppliers, significantly reducing the environmental footprint of logistics operations.

More than 90% of Reynders' materials originate from European countries, with Luxembourg, France, and Germany serving as the primary sourcing hubs. This regional concentration supports shorter delivery times (typically 2-3 days), reduces transportation emissions, and ensures compliance with EU regulatory standards for quality and sustainability.

Luxembourg

Primary sourcing hub

France

Major European supplier

Germany

Regional materials partner

USA

Specialized materials

UK

Select components

Material Certification

A significant share of biological materials used by Reynders consists of FSC-certified paper and cardboard, ensuring that fibre-based inputs are sustainably sourced and compliant with the EU's cascade principle of resource use (prioritising reuse and recycling before energy recovery or disposal).

E5-5 | Resource outflows

Circular Product Design

Reynders applies circularity principles in product design by:

- ✓Promoting recyclable and compostable label constructions

- ✓Using FSC-certified paper and mono-material plastic films where possible

- ✓Reducing material thickness and optimising formats to minimise waste

- ✓Exploring linerless label technologies to eliminate backing waste

Waste Management

Relevant Waste Streams

- •Paper and cardboard waste, including label liners, packaging, and production residues

- •Plastic waste, such as films, packaging materials, and substrates used in printing

- •Mixed and composite packaging waste, combining paper, plastic, and adhesives

- •Hazardous waste, primarily inks, varnishes, solvents, toners, and adhesive residues

- •Municipal and commercial waste, arising from general operations and maintenance

- •Metal and wooden packaging, used for material storage and transport

Waste Generation and Treatment (2024)

| Waste Category | Amount (tonnes) | % |

|---|---|---|

| Total Waste Generated | 5 177 | 100% |

| Waste Diverted from Disposal | 2 107 | 41% |

| - Preparation for reuse | 0 | 0% |

| - Recycling | 2 107 | 41% |

| - Other recovery operations | 0 | 0% |

| Waste Directed to Disposal | 3 070 | 59% |

| - Incineration | 2 542 | 49% |

| - Landfilling | 528 | 10% |

| - Other disposal operations | 0 | 0% |

Hazardous Waste

Non-Hazardous Waste

Waste Treatment Allocation Methodology

For waste streams where the exact treatment route was not known, conservative allocation factors were applied based on typical waste management practices in Western Europe, using Eurostat statistics as reference. These assumptions were used solely for calculation purposes where no primary information on the actual treatment route was available.

E5-IRO-1 | Description of the processes to identify and assess material resource use and circular economy-related impacts, risks and opportunities

Materiality Assessment Results

The double materiality assessment for Reynders label printing identified resource use and circular economy (ESRS E5) as material from an impact perspective, but non-material from a financial perspective.

Material impacts identified:

- •Material selection and resource inflows: Operations rely on paper, plastic (PP, PE), inks, and adhesives. Impact mitigated through supplier collaboration, FSC-certified paper, material thinning, and the Triple R program.

- •Resource efficiency in production: Resource inflows continuously monitored under ISO 14001, with sites optimising material use relative to output and applying circular design principles.

- •Product design: Promotes recyclable, compostable, and linerless label constructions, contributing to improved recyclability downstream.

- •Waste management: Waste treated as a key performance indicator, with separation of waste streams and recycling of production residues under ISO 14064 and ISO 14001 frameworks.

S1-SBM-3 | Interaction of material impacts, risks and opportunities with strategy and business model

Scope and Workforce Overview

All people in Reynders label printing's own workforce who can be materially impacted by the undertaking are included in the scope of disclosure under ESRS 2.

Reynders' workforce primarily consists of permanent, full-time employees engaged in printing, production, logistics, and administrative functions across its European sites. No significant adverse impacts have been identified within the own workforce. All employment contracts comply with national labour laws, and fixed-term roles are used only to cover seasonal production peaks. Health and safety conditions are closely monitored under ISO 45001, with incident reporting and PPE compliance implemented at all production sites. Temporary and agency workers are covered by the same occupational safety and fair pay provisions as permanent employees.

Positive Impacts on Workforce

Reynders fosters several positive impacts on its workforce through structured employment practices, training, and social dialogue:

- •Secure employment & fair pay: Nearly all employees hold permanent contracts, and salary levels meet or exceed sectoral minimums, verified annually via internal and external benchmarking.

- •Work-life balance & family support: Flexible shift patterns, part-time opportunities, and on-site childcare facilities (e.g., De Kleine Prins at the Boechout campus) help employees balance family and work responsibilities.

- •Health and safety culture: Regular safety briefings, incident tracking, and certified management systems strengthen occupational well-being.

- •Social dialogue & freedom of association: Reynders is a signatory to the ETI Base Code, guaranteeing the right to union representation and collective bargaining. Employee councils and QA meetings ensure transparent communication and participatory decision-making.

- •Equal treatment & inclusion: The company enforces a strict Code of Conduct prohibiting discrimination, harassment, and inequality, ensuring equal pay for men and women in equivalent roles.

S1-1 | Policies for own workforce

Code of Conduct

Reynders label printing has implemented internal rules through its Code of Conduct, which applies to all employees across its sites. The Code covers:

- •Respect for human rights and dignity

- •Equal treatment, diversity, and zero tolerance of discrimination or harassment

- •Safe and healthy working conditions

- •Fair remuneration and compliance with labour laws

- •Freedom of opinion and open communication

- •Compliance with applicable laws and internal company rules

Scope of Application

The Code of Conduct applies to all Reynders employees in every country of operation. It defines expectations for ethical conduct and workplace behaviour. There are no exclusions for own workforce; suppliers and business partners are covered under separate supplier and business conduct guidelines.

Responsibility

The Group Management Board bears overall responsibility for the implementation and compliance with the Code of Conduct. At the operational level, local management and HR departments ensure that employees understand and follow the principles outlined in the Code.

Alignment with International Standards

Reynders label printing's Code of Conduct and ethical standards are aligned with the ETI Base Code (Ethical Trading Initiative), to which the company formally subscribes. The ETI Base Code is founded on the conventions of the International Labour Organization (ILO) and is consistent with the UN Guiding Principles on Business and Human Rights and the Universal Declaration of Human Rights.

By endorsing the ETI Base Code, Reynders commits to:

- •Employment that is freely chosen, without forced or bonded labour

- •Respect for freedom of association and the right to collective bargaining

- •Safe and hygienic working conditions and the prohibition of child labour

- •Equal opportunities and non-discrimination in all employment practices

- •Fair wages, reasonable working hours, and humane treatment

These commitments are embedded in Reynders' internal management systems and policies, supported by certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), and ISO 45001 (occupational health and safety), ensuring continuous monitoring and compliance with both international and national labour standards.

Policy Confirmations

S1-2 | Processes for engaging with own workers and workers' representatives

The perspectives of Reynders' own workforce are taken into account in decisions or activities aimed at managing the actual and potential impacts that influence them. Employee engagement occurs through direct communication with own workforce and regular consultations with workers' representatives.

Engagement Stages and Frequency

Employee engagement occurs at several stages:

- •Operational stage: Daily and bi-weekly meetings address production and safety issues

- •Strategic and policy stage: Regular reviews of working conditions, wages, and safety under ISO 9001 and ISO 45001 frameworks

- •Annual stage: Salary benchmarking and HR reviews

Type of engagement: two-way communication, employee feedback sessions, and consultation through workers' councils and union bodies.

Integration of Workforce Perspectives

Input from employees and their representatives is used to identify workplace improvements (health, safety, ergonomics), review working-time organisation, and adjust training and development opportunities. Feedback is integrated through HR management and site leadership teams.

Responsibility

Operational responsibility lies with site management and HR departments, under oversight of the Group HR Director. Implementation is monitored through the ISO-certified management systems and regular internal audits.

Human Rights Agreement

Reynders is a signatory to the ETI Base Code, which guarantees core human rights at work, including freedom of association and collective bargaining. The company assesses the effectiveness of its engagement with its own workforce through regular management reviews, audit findings, and employee feedback mechanisms.

S1-3 | Processes to remediate negative impacts

Channels for Raising Concerns

Reynders has established channels for raising concerns and needs and supports their availability in the workplace for its own workforce. The company has not identified any significant negative impact that it has caused or contributed to affecting persons within its own workforce.

Reynders provides multiple formal and informal channels that allow employees to raise concerns or express needs directly to management:

- •Direct communication during daily briefings, QA meetings, and production meetings

- •HR and line management – employees can approach supervisors or HR staff at any time

- •Works councils and union representatives at European sites, which facilitate structured dialogue

- •Internal email and in-person meetings used to report issues or request support

These channels are established directly by the enterprise, and the company has a grievance/complaints handling mechanism related to employee matters.

Support and Tracking

Communication and complaint mechanisms are supported through:

- •Regular reminders during ISO 9001 / ISO 45001 audits and trainings

- •Posting of contact details for HR and management at sites

- •Integration of the Code of Conduct in onboarding and training processes

Issues raised through these channels are handled by HR and site management. Tracking occurs through meeting records, audit reports, and incident logs (especially for safety-related topics). Effectiveness is ensured through periodic management reviews, ISO 45001 safety committees, and follow-up actions documented as part of the continuous-improvement process.

Awareness and Protection

People in Reynders' own workforce are aware of and trust the established structures/processes to raise concerns. Employee familiarity with communication and grievance processes is maintained through regular communication, safety meetings, and Code-of-Conduct training. Trust is reinforced by Reynders' open-door culture, frequent direct dialogue, and active presence of workers' representatives.

The company has policies in place to protect individuals who use mechanisms to address their concerns and needs against retaliation.

S1-4 | Actions and resources related to own workforce

Reynders label printing has taken actions to address material impacts, manage risks, and pursue opportunities related to its own workforce. The company actively promotes fair working conditions, employee well-being, and inclusion across all production sites.

Implemented Measures for Positive Impacts

- •Permanent employment and fair remuneration: Salaries meet or exceed national and sectoral minimum wages, reviewed annually through internal and external benchmarking

- •Safe and healthy workplaces: One site is certified under ISO 45001, and all sites operate safety committees, apply PPE standards, solvent-extraction systems, and camera monitoring

- •Work–life balance support: Flexible shift models, part-time options, and an on-site childcare facility ("De Kleine Prins") at the Boechout campus

- •Employee development: Reynders cooperates with training partners to offer professional development

Effectiveness Tracking

The effectiveness of workforce-related initiatives is monitored through:

- •Regular management and QA meetings at site and group level

- •Health and safety KPIs such as monthly incident-rate tracking and corrective-action reviews

- •Annual salary reviews and staff turnover analysis to monitor fairness and retention

- •Internal audits under ISO 9001 and ISO 45001 frameworks

Employee feedback is gathered through day-to-day communication, supervisory meetings, and local employee representatives, ensuring that actions remain responsive to workforce needs.

Resource Allocation

Human-resources management and occupational health and safety are coordinated by the Group HR and EHS departments, supported by local management teams at each site. Resources include dedicated HSE officers at production sites, annual training budgets for professional and safety training, investments in workplace infrastructure (ventilation, ergonomic equipment, safety systems, childcare facilities), and continuous improvement programs under ISO 9001/45001 certifications.

S1-5 | Targets related to own workforce

Reynders has not yet established specific sustainable metrics or set formal targets for material areas related to its own workforce. The company monitors workforce-related performance through existing management systems and continuous improvement processes.

S1-6 | Characteristics of the undertaking's employees

Total Employees by Gender

| Gender | Headcount |

|---|---|

| Male | 447 |

| Female | 245 |

| Total | 692 |

Employee Turnover

Employees who left during reporting period

Employee turnover rate

Employees by Country

| Country | Headcount |

|---|---|

| Belgium (BE) | 387 |

| Poland (PL) | 92 |

| Germany (DE) | 80 |

| Spain (ES) | 46 |

| France (FR) | 42 |

| India (IN) | 28 |

| Other countries | 17 |

Employees by Gender, Contract Type, and Employment Type

| Gender | Contract Type | Employment Type | Number |

|---|---|---|---|

| Male | Permanent | Full time | 437 |

| Male | Permanent | Part time | 10 |

| Female | Permanent | Full time | 222 |

| Female | Permanent | Part time | 23 |

Methodology

Data related to Reynders' own workforce (including headcount, employment type, gender distribution, training hours, and health & safety indicators) were collected at the level of each subsidiary within the Reynders Group and subsequently consolidated at the Group level for reporting purposes. Each production site maintains its own HR records and payroll systems, which serve as the primary data source. The consolidation process was coordinated by the Group HR and Sustainability departments, ensuring consistency across countries and business units.

S1-7 | Characteristics of non-employee workers

Reynders has people in its workforce who are not employees. These are primarily agency workers at Reynders Etiketten Deutschland.

Total non-employees in own workforce

Self-employed people

Agency employees

Methodology

Non-employee workers are reported in headcount and tracked through the time recording system (ATOSS) at Reynders Etiketten Deutschland. The number of agency workers is not included in the total employee count but is tracked separately.

S1-8 | Collective bargaining coverage and social dialogue

Employees covered by collective bargaining agreements

Percentage of total employees covered

S1-9 | Diversity metrics

Gender Representation in Top Management

| Gender | Number | Percentage |

|---|---|---|

| Male | 22 | 92% |

| Female | 2 | 8% |

Top management is defined as one and two levels below the administrative and supervisory bodies.

Distribution by Age Group

| Age Group | Number | Percentage |

|---|---|---|

| Under 30 years | 112 | 16% |

| 30-50 years | 340 | 49% |

| Over 50 years | 240 | 35% |

S1-10 | Adequate wages

Confirmation of Adequate Wages

All employees across all Reynders entities are paid adequate wages, in line with applicable benchmarks:

S1-11 | Social protection

Coverage for All Employees

All employees in Reynders' own workforce are covered by social protection, through public programs or through benefits offered, against loss of income for the following cases:

S1-12 | Persons with disabilities

Number of persons with disabilities amongst employees

Percentage of persons with disabilities amongst employees

Context and Methodology

The data is based on official disability recognition systems in the respective countries. In Germany, the value is based on the Schwerbehindertenabgabe 2024 (severe disability levy), verified through disability certificates. This declaration must be reported annually to the Federal Employment Agency to calculate any required compensation payment. In France, recognition of disabled worker status is delivered by a designated organization.

S1-13 | Training and skills development metrics

Performance and Career Development Reviews by Gender

| Gender | Number Participated | Percentage |

|---|---|---|

| Male | 227 | 51% |

| Female | 98 | 40% |

Average Training Hours by Gender

| Gender | Total Training Hours | Average per Employee |

|---|---|---|

| Male | 9,106.25 | 20 |

| Female | 3,445.00 | 14 |

S1-14 | Health and safety metrics

Health and Safety Management System Coverage

People covered by health and safety management system

Percentage of workforce covered

Fatalities

| Type of Workers | Result of Fatalities | Number |

|---|---|---|

| Employee workers | Fatalities as a result of work-related injuries | 0 |

| Employee workers | Fatalities as a result of work-related ill health | 0 |

Number of recordable work-related accidents

Rate of recordable work-related accidents

Cases of recordable work-related ill health

Total number of lost workdays due to work-related injuries, illnesses, and fatalities

S1-15 | Work-life balance metrics

Family-Related Leave Entitlement

All employees are entitled to family-related leave through social policy and/or collective agreements.

Number of employees entitled to take family-related leave

Percentage of employees entitled

Employees Who Took Family-Related Leave by Gender

| Gender | Number | Percentage |

|---|---|---|

| Male | 54 | 12% |

| Female | 52 | 21% |

S1-16 | Compensation metrics (pay gap and total compensation)

Gender Pay Gap

Difference of average pay levels between female and male employees

Note: First time gathering this data. Next year, we will examine the numbers in detail as we do not yet account for parity differences across countries.

CEO Pay Ratio

Ratio between remuneration of highest paid employee and the median

S1-17 | Incidents, complaints and severe impacts in the area of human rights

Number of incidents of discrimination

Total complaints made through workforce channels

Complaints filed to National Contact Points for OECD

Serious Human Rights Incidents

There have been no cases of serious human rights incidents (e.g., forced labour, trafficking or child labour) involving own staff during the reporting period.

S2-SBM-3 | Interaction of material impacts, risks and opportunities with strategy and business model

All workers in Reynders' value chain who may be significantly affected by the enterprise are included in the scope of disclosure under ESRS 2.

Workers in the Value Chain

Reynders' value chain includes mainly workers employed by raw material suppliers — primarily producers of paper, film, inks, and adhesives. These workers are indirectly affected through Reynders' purchasing decisions and supplier requirements. The company's own direct suppliers operate mostly in Europe and are expected to comply with international labour and human rights standards under Reynders' Supplier Code of Conduct and contractual clauses.

Risk Assessment

The majority of Reynders' suppliers are based in Europe, where the risk of child or forced labour is low. The company does not source raw materials directly from high-risk geographies. While certain chemical or paper-based inputs may originate from global supply chains, Reynders does not identify any specific country or commodity with significant risk of child or forced labour. No such cases were reported during the reporting period.

Positive Impacts

Positive impacts are achieved through:

- •Adherence to the ETI Base Code, which promotes decent work and ethical labour practices

- •Inclusion of explicit prohibitions of child labour and anti-corruption clauses in supplier contracts

- •Preference for FSC-certified and ISO-compliant suppliers, supporting responsible resource sourcing

- •Long-term partnerships with European suppliers that encourage stable employment and compliance with social standards

While Reynders has not yet implemented systematic human-rights screening or audits of its suppliers, these measures collectively foster ethical business conduct and risk prevention within the extended value chain.

S2-1 | Policies related to workers in the value chain

Supplier Expectations

Reynders label printing addresses value chain labour standards through its Code of Conduct and adherence to the ETI Base Code. These frameworks set expectations for suppliers regarding:

- •Respect for human rights and decent working conditions

- •Prohibition of forced, bonded, and child labour

- •Non-discrimination, fair wages, and safe working environments

- •Ethical business conduct, including anti-corruption provisions

Suppliers are expected to comply with these principles as part of contractual agreements.

Scope of Application

The policy applies to direct suppliers and contractors providing goods and services to Reynders' production sites. It does not currently extend to sub-tier suppliers (e.g., raw material extraction or processing stages), as there is no formal due diligence system or structured audit process in place.

Responsibility

Responsibility for implementing and monitoring compliance lies with the Group Management Team and the Procurement Department, under oversight from senior management. Local site managers ensure that supplier requirements are applied in day-to-day procurement and operational processes.

Alignment with International Standards

Reynders subscribes to the ETI Base Code (Ethical Trading Initiative) and aligns its supplier expectations with its principles. Additionally, the company's management systems are certified under ISO 9001 (quality) and ISO 14001 (environmental management), reinforcing compliance and ethical practices in the supply chain.

Stakeholder interests—particularly those of customers in regulated sectors (food, cosmetics, pharmaceuticals)—influence Reynders' social compliance approach. These clients often require adherence to ethical and safety standards (e.g., GMP, BRC/IoP certifications), indirectly strengthening Reynders' human rights commitments within the value chain.

Topics Explicitly Addressed

S2-4 | Actions and resources related to workers in the value chain

Current Status

Reynders label printing has not yet adopted specific actions to address impacts, risks, or opportunities related to workers in its value chain, primarily because:

- •The company operates within a business-to-business (B2B) printing and labelling sector, where suppliers are typically established companies within Europe and subject to strict local labour, environmental, and safety regulations

- •Reynders therefore considers the risk of human rights violations, forced or child labour, or unsafe working conditions in its direct supply chain to be low

- •The company's current approach focuses on compliance-based management, relying on the ETI Base Code, Code of Conduct, and contractual clauses prohibiting child labour and corruption, rather than active due diligence or audit processes

- •No significant incidents or risk indicators have been identified to date that would have triggered the need for targeted action plans

Human Rights Incidents

There were no serious human rights incidents reported involving workers in the value chain during the reporting period.

S2-5 | Targets related to workers in the value chain

Reynders has not yet established specific sustainable metrics or set formal targets for material areas related to value chain workers. The company monitors supply chain performance through existing procurement and compliance processes.

S4-SBM-3 | Interaction of material impacts, risks and opportunities with strategy and business model

All affected consumers and end-users who may be significantly impacted are included in the scope of disclosure under ESRS 2.

Consumers and End-Users Affected

Reynders label printing's operations primarily impact business customers in regulated sectors, including:

- •Pharmaceutical companies: Where accurate dosage, barcoding, and traceability information are critical for patient safety

- •Cosmetics and personal care producers: Requiring precise labelling to ensure correct product identification, allergen information, and legal compliance

- •Food and beverage manufacturers: Dependent on compliant and legible labels to provide consumers with accurate ingredient and nutritional data

Through these clients, Reynders indirectly impacts end consumers who rely on accurate and compliant product labelling for safe use and informed decision-making.

Positive Impacts

Reynders generates positive downstream impacts through:

- •Implementation of ISO 9001 quality management systems and BRCGS/IoP certification ensuring label accuracy and hygiene

- •Application of Good Manufacturing Practices (GMP) in pharmaceutical labelling to prevent mislabelling and contamination

- •Use of low-migration inks and strict compliance with REACH to eliminate chemical exposure for consumers

- •Deployment of 100% camera inspection systems, digital artwork control, and serialisation to minimise labelling errors

- •Transparent communication of chemical safety (SVHC > 0.1%) and responsible logo use (FSC, compostability) to support consumer trust

S4-1 | Policies related to consumers and end users

Current Approach

Reynders does not have a standalone internal policy specifically dedicated to consumers or end users. However, consumer-related aspects are integrated into existing management systems and certifications, namely:

- •ISO 9001 (Quality Management System)

- •BRCGS/IoP (Packaging and Packaging Materials Standard)

- •GMP (Good Manufacturing Practice) procedures for pharmaceutical and food labelling

These systems ensure that product quality, safety, and regulatory compliance are maintained throughout production and delivery, effectively serving the purpose of protecting end users and ensuring reliable information and safe product use.

Policy Coverage

The disclosed policies apply to all consumers and/or end users who are affected by Reynders' products and services.

International Alignment

Reynders' policies are aligned with relevant internationally recognized instruments, including the UN Guiding Principles on Business and Human Rights.

Compliance Record

There have been no cases in the value chain of non-compliance with human rights concerning consumers and end-users during the reporting period.

S4-4 | Actions and resources related to consumers and end users

The undertaking has taken actions to address material impacts, manage material risks, and pursue material opportunities related to consumers and/or end users. Policies are in place to protect individuals who use these mechanisms from retaliation.

Implemented Actions for Positive Impacts

Key implemented actions include:

- •ISO 9001-certified quality management system ensuring consistent process control, traceability, and compliance with legal labelling requirements

- •BRCGS/IoP and GMP certification, which guarantee hygiene and quality standards for food and pharmaceutical labelling

- •Use of low-migration inks and REACH compliance to eliminate consumer exposure to hazardous substances

- •100% camera inspection systems and digital artwork approval to prevent errors in printed information, ensuring product traceability

- •Customer transparency and communication – clear disclosure of chemical content above 0.1% (SVHC) and correct application of FSC and compostability logos

Sustainability Measures

Reynders continuously develops sustainability measures that both reduce environmental impact and enhance consumer trust in product safety:

- •Material reduction and eco-design: Together with suppliers and customers, Reynders promotes thinner but equally durable substrates (e.g., PP 60 μ → 50 μ, PE 100 μ → 85 μ, backing paper 70–80 g/m² → 60 g/m²). These adjustments reduce raw-material demand, energy and water use, and waste generation throughout the product life cycle

- •Triple R (Reduce–Reuse–Recycle) program: EURO pallets are reused through an exchange system with suppliers and customers

- •Sustainable logistics: Since 2015, Reynders and its key suppliers have optimized deliveries — reducing frequency from five to four per week and grouping orders to increase pallet utilization and reduce CO₂ emissions from transport

- •Digitalization and paper reduction: Orders, shipping lists, and invoices are transmitted electronically via EDI

Incident Reporting

No serious human rights issues or incidents connected to the undertaking's consumers and/or end users were reported during the reporting period.

S4-5 | Targets related to consumers and end users

Reynders has not yet established specific sustainable metrics or set formal targets for material areas related to affected consumers and/or end users. The company monitors consumer-related performance through existing quality management systems and customer feedback processes.

CSR and Community Engagement

Reynders label printing integrates social responsibility into its operations through long-term community, cultural, and educational initiatives across its global sites.

Community projects and charitable support

- •Educational support in India – Project "Bhagiya": Reynders finances the rent and operation of two basement schools in Rajasthan, covering the salaries of four full-time teachers. These schools provide education for underprivileged children who would otherwise follow their parents to work.

- •Cultural regeneration in Belgium – "Boechout Forwards": The company co-developed a cultural and social meeting center on the site of the former "California" soup factory, in partnership with the Municipality of Boechout and local private actors. The center now hosts community events, theater, and educational activities.

- •Recreation and biodiversity – "Play and Recreation Forest": Since 2009, Reynders has maintained a 4.1-hectare forest in Boechout, which is open to youth organizations and local associations. More than 5,000 trees and 2,900 shrubs have been planted. The site includes the restored 17th-century Courtois Chapel and hosts the annual "Nature Run" and family events for employees.

- •Inclusive procurement: Reynders deliberately selects local suppliers that employ or integrate people with disabilities, psychiatric patients, or refugees.

- •Daycare center for employees: Since 2005, part of the Boechout logistics building hosts the daycare "De Kleine Prins", which provides preschool care for twelve children of Reynders employees.

Educational and training initiatives

- •Reynders cooperates with the Belgian Packaging Institute (BVI), providing expertise for professional training courses in packaging and labeling.

- •Through industry associations such as FINAT, UNFEA, and ECPA, Reynders participates in workshops and training programs related to lean management, waste reduction, and sustainability.

- •From 2024, Reynders guarantees at least five training days per employee annually, emphasizing on-the-job learning and safety education.

Environmental and volunteering-related actions

- •Employees and local residents participate in the maintenance of the Play Forest and biodiversity initiatives (e.g., insect hotel and local reforestation).

- •The company regularly sponsors and organizes community sport and nature events to raise awareness about sustainability and conservation.

We Follow Ethical Principles

In our daily work, we follow ethical and moral principles, and we expect all our employees and collaborators to adhere to them as well.

G1-GOV-1 | The role of the administrative, supervisory and management bodies

Tasks of administrative, management and supervisory bodies

At Reynders Label Printing, the administrative and management bodies are responsible for ensuring that all business activities are conducted in accordance with ethical, legal, and sustainability principles set out in the company's Code of Conduct and certified management systems (ISO 9001, ISO 14001, ISO 45001).

Their key tasks include:

- •Overseeing compliance with national and international labour, environmental, and quality standards.

- •Ensuring that ethical principles such as integrity, fairness, anti-corruption, and respect for human rights are embedded in daily operations and supplier relationships.

- •Monitoring the implementation of health, safety, and environmental management systems across all sites.

- •Reviewing sustainability performance indicators and progress toward continuous improvement targets.

- •Approving strategic initiatives related to quality, product safety, and circular economy practices.

Expertise of administrative, management and supervisory bodies

The administrative, management, and supervisory bodies of Reynders Label Printing possess a broad range of professional expertise and leadership skills that enable them to effectively guide, oversee, and strategically develop the organisation. Their key areas of competence include:

- •Knowledge of printing and packaging industry regulations – expertise in EU and national legislation governing product labelling, traceability, and consumer safety, particularly in the food, cosmetics, and pharmaceutical sectors.

- •Sustainability and environmental management – in-depth understanding of ISO 14001, FSC certification, and circular economy practices to ensure environmentally responsible operations.

- •Occupational health and safety management – practical experience in implementing ISO 45001 standards and ensuring safe working conditions across production sites.

- •Quality management and product safety – strong command of ISO 9001 and BRCGS/IoP certification systems, ensuring high-quality output, compliance with REACH, and chemical safety in production.

- •Corporate ethics, compliance, and responsible supply chain governance – awareness of the ETI Base Code and anti-corruption principles, as well as due diligence in supplier relations.

- •Strategic and managerial capabilities – ability to formulate long-term goals, allocate resources efficiently, and guide continuous improvement initiatives across the group.

- •Financial and operational control – experience in cost optimisation, auditing, and performance monitoring to ensure economic stability and transparent governance.

These competencies enable Reynders' management bodies to ensure ethical business conduct, operational excellence, and long-term sustainability across all subsidiaries and markets.

G1-1 | Policies for business conduct

Key contents of policy

The Code of Conduct includes commitments to:

- •Conducting all business operations with honesty, transparency, and fairness.

- •Prohibiting bribery, corruption, and conflicts of interest.

- •Ensuring equal opportunity, non-discrimination, and respectful workplace behaviour (details already covered under S1-1).

- •Upholding data confidentiality, intellectual property rights, and responsible communication with customers and partners.

- •Promoting safety, quality, and environmental stewardship as part of daily business ethics.

Scope of policy

No exclusions.

Responsibility for implementation

The Group Management Team (executive level) holds ultimate responsibility for ensuring compliance with the Code of Conduct. Implementation is coordinated by local site managers under the oversight of Quality, Safety, and Environmental Managers.

Stakeholder interests in policy setting

Stakeholder expectations are reflected through:

- •Customer requirements and audits (e.g., BRCGS/IoP, GMP, REACH).

- •Employee engagement and feedback channels.

- •Supplier collaboration within the framework of the ETI Base Code.

- •Regulatory standards and certifications ensuring compliance with external expectations.

Availability of policies

The Code of Conduct is publicly available on the company website and shared internally via management communications and onboarding materials. Suppliers are made aware of its principles through contracts and compliance documentation.

Corporate culture

Reynders promotes its corporate culture through:

- •A clear Code of Conduct setting behavioural expectations for integrity and collaboration.

- •Regular internal communication, training, and management briefings reinforcing ethical and safety standards.

- •ISO management reviews and audits, which assess adherence to company values, safety, and compliance.

- •Engagement of local leadership to ensure the culture of responsibility, transparency, and sustainability is maintained across all sites.

Corporate culture is evaluated indirectly through ISO audits, HR processes, and absence of reported misconduct cases.

Whistleblowing and investigation mechanisms

The Code of Conduct contains a "speaking-up" section referencing the EU Whistleblower Directive (applicable due to >50 employees). Employees can report unethical or unlawful behaviour through internal channels, ensuring non-retaliation and confidentiality.

Internal whistleblower reporting channels

Reynders Label Printing has established internal whistleblower reporting channels in compliance with the Belgian transposition of the EU Whistleblower Directive (2019/1937).

Reports can be submitted in writing or verbally, through the following official channels:

- • By telephone: +32 (0)3 460 14 27 (office hours: 9:00–16:00, Fridays until 14:00)

- • By email: [email protected]

- • By post: Reynders Label Printing, attn. An Meeussen, Nijverheidsstraat 3, 2530 Boechout, Belgium

The designated reporting officer (meldingsbeheerder) is An Meeussen (HR Manager), responsible for receiving and following up on internal reports, maintaining communication with the whistleblower, and ensuring confidentiality.

Reports can be made in Dutch, French, or English. All reports are recorded in a confidential register in accordance with Article 20 of the Belgian Whistleblower Protection Law (28 November 2022).

Measures to protect whistleblowers

Reynders Label Printing ensures strict confidentiality for the identity of the whistleblower and any third parties involved.

Protection measures, in accordance with Articles 23–32 of the Belgian Whistleblower Protection Law, include:

- • Prohibition of retaliation (e.g., dismissal, demotion, harassment, discrimination).

- • Confidential handling of all reports and secure storage of related information.

- • Acknowledgement of receipt within seven days and feedback within three months of the initial report.

- • Anonymous reporting options and impartial follow-up by the reporting officer.

These safeguards are designed to encourage safe and responsible reporting of potential breaches of EU or national law without fear of adverse consequences.

Anti-corruption and anti-bribery policies

Reynders has policies on anti-corruption or anti-bribery consistent with the United Nations Convention against Corruption.

Training on business conduct

Training on business ethics and Code of Conduct awareness is included in onboarding programs and periodic internal briefings. It targets all employees, particularly management and those in roles involving supplier relations, procurement, and customer communication. Frequency and scope vary by site but are aligned with ISO and ETI audit requirements.

Functions most at risk

Functions identified as most exposed to corruption or bribery risks include:

- •Procurement and supplier relations, due to supplier selection and negotiation processes.

- •Sales and business development, especially in international contexts involving contract bidding.

- •Finance and administration, responsible for approving payments and monitoring compliance.

All these functions are governed by anti-bribery clauses in the Code of Conduct and reinforced through ETI Base Code adherence.

G1-2 | Management of relationships with suppliers

Approach to supplier relationships

Reynders Label Printing maintains long-term partnerships with suppliers of paper, films, inks, foils, and adhesives that are essential for its label and shrink sleeve production. The company's supplier relationships are guided by ethical, sustainable, and transparent business practices, while also ensuring the high quality and safety standards required by its customers — notably GMP (Good Manufacturing Practice) for pharmaceuticals and BRCGS/IoP certification for the food industry.

Because the substrates used (self-adhesive papers and films) are produced almost exclusively by multinational manufacturers, Reynders seeks to source regionally whenever possible. Most materials are delivered from European subsidiaries located in Belgium and the Netherlands, with an average delivery time of 2–3 days, minimizing transport-related emissions and ensuring operational continuity.

The company also supports socially responsible sourcing by partnering with organizations that employ and integrate people with disabilities, psychiatric patients, or refugees, aligning its procurement approach with broader CSR goals.

Supplier management is further supported by adherence to the ETI Base Code, REACH compliance, and ISO 14001 environmental management systems, ensuring environmental and ethical compliance across its value chain.

Social and environmental criteria for supplier selection

Social and environmental criteria are embedded in Reynders' procurement processes and supplier evaluation. These include:

- •Environmental certifications such as FSC for paper-based substrates and ISO 14001 for suppliers with formal environmental management systems.

- •REACH compliance to guarantee the safe use and traceability of chemical substances.

- •ETI Base Code adherence, ensuring suppliers respect ethical working conditions and human rights.

- •Local sourcing preference, especially for packaging and service providers, to minimize transportation distances, emissions, and lead times.

- •Social inclusion initiatives, where suppliers are chosen not only based on quality and price, but also their contribution to social employment and integration programs.

G1-6 | Payment practices

Average invoice payment time

Outstanding legal proceedings

Standard payment terms by supplier category

We do not have a formal internal policy, but we consistently pay in time and in advance of the deadline (most vendors offer 30 days net and 14 days, 2% discount as standard) to benefit from the discount.

Conclusion

Thank you for reading our first consolidated sustainability report.

This report presents a transparent view of our ESG activities and our commitments to all stakeholders. We are aware that the path to sustainability is a long-term process that requires constant effort and improvement.

We believe that our steps in environmental responsibility, social responsibility, and proper corporate governance contribute not only to our business success, but also to a better future for everyone.

Together we create a sustainable future.

Reynders label printing

Sustainability Report 2024

Contact:

www.reynders.com

ESRS Data Point Index

This index provides a comprehensive mapping of all European Sustainability Reporting Standards (ESRS) datapoints disclosed in this report.

ESRS Compliance Framework

The datapoints below follow the structure defined in the European Sustainability Reporting Standards (ESRS), covering General Disclosures (ESRS 2), Environmental (E1-E5), Social (S1-S4), and Governance (G1) topics.

| ESRS Topic | Datapoint ID | Section |

|---|---|---|

| ESRS 2|BP-1 | bp-1-5-a | BP-1 |

| ESRS 2|BP-1 | bp-1-5-b-i | BP-1 |

| ESRS 2|BP-1 | bp-1-5-b-ii | BP-1 |

| ESRS 2|BP-1 | bp-1-5-c | BP-1 |

| ESRS 2|BP-1 | bp-1-5-d | BP-1 |

| ESRS 2|BP-1 | bp-1-5-e | BP-1 |

| ESRS 2|BP-2 | bp-2-9 | BP-2 |

| ESRS 2|BP-2 | bp-2-10 | BP-2 |

| ESRS 2|BP-2 | bp-2-10-a | BP-2 |

| ESRS 2|BP-2 | bp-2-10-b | BP-2 |

| ESRS 2|BP-2 | bp-2-10-c | BP-2 |

| ESRS 2|BP-2 | bp-2-10-d | BP-2 |

| ESRS 2|GOV-1 | gov-1-21-a | GOV-1 |

| ESRS 2|GOV-1 | gov-1-21-a-1 | GOV-1 |

| ESRS 2|GOV-1 | gov-1-21-b | GOV-1 |

| ESRS 2|GOV-1 | gov-1-21-d-1 | GOV-1 |

| ESRS 2|GOV-1 | gov-1-21-d-2 | GOV-1 |

| ESRS 2|GOV-1 | gov-1-21-e | GOV-1 |

| ESRS 2|GOV-1 | gov-1-21-e-1 | GOV-1 |

| ESRS 2|GOV-1 | gov-1-22-c | GOV-1 |

| ESRS 2|GOV-1 | gov-1-23-a | GOV-1 |

| ESRS 2|GOV-1 | gov-1-23-b | GOV-1 |

| ESRS 2|GOV-2 | gov-2-26-a | GOV-2 |

| ESRS 2|GOV-2 | gov-2-26-b | GOV-2 |

| ESRS 2|GOV-2 | gov-2-26-c | GOV-2 |

| ESRS 2|GOV-2 | gov-2-ar-6 | GOV-2 |

| ESRS 2|GOV-3 | gov-3-29 | GOV-3 |

| ESRS 2|GOV-3 | gov-3-29-b | GOV-3 |

| ESRS 2|GOV-4 | gov-4-30 | GOV-4 |

| ESRS 2|GOV-4 | gov-4-31 | GOV-4 |

| ESRS 2|GOV-4 | gov-4-32 | GOV-4 |

| ESRS 2|GOV-5 | gov-5-33 | GOV-5 |

| ESRS 2|GOV-5 | gov-5-34 | GOV-5 |

| ESRS 2|GOV-5 | gov-5-35-a | GOV-5 |

| ESRS 2|GOV-5 | gov-5-35-b | GOV-5 |

| ESRS 2|GOV-5 | gov-5-36 | GOV-5 |

| ESRS 2|SBM-1 | sbm-1-40-a-i | SBM-1 |

| ESRS 2|SBM-1 | sbm-1-40-a-ii | SBM-1 |

| ESRS 2|SBM-1 | sbm-1-40-e | SBM-1 |

| ESRS 2|SBM-1 | sbm-1-40-f | SBM-1 |

| ESRS 2|SBM-1 | sbm-1-40-g | SBM-1 |

| ESRS 2|SBM-1 | sbm-1-42-a | SBM-1 |

| ESRS 2|SBM-1 | sbm-1-42-b | SBM-1 |

| ESRS 2|SBM-1 | sbm-1-42-c | SBM-1 |

| ESRS 2|SBM-2 | sbm-2-45-a-i | SBM-2 |

| ESRS 2|SBM-2 | sbm-2-45-a-ii | SBM-2 |

| ESRS 2|SBM-2 | sbm-2-45-a-iii | SBM-2 |

| ESRS 2|SBM-2 | sbm-2-45-a-iv | SBM-2 |

| ESRS 2|SBM-2 | sbm-2-45-a-v | SBM-2 |

| ESRS 2|SBM-2 | sbm-2-45-b | SBM-2 |

| ESRS 2|SBM-2 | sbm-2-45-c-i | SBM-2 |

| ESRS 2|SBM-3 | sbm-3-48-a | SBM-3 |

| ESRS 2|SBM-3 | sbm-3-48-b | SBM-3 |

| ESRS 2|SBM-3 | sbm-3-48-c | SBM-3 |

| ESRS 2|SBM-3 | sbm-3-48-d | SBM-3 |

| ESRS 2|IRO-1 | iro-1-53-a | IRO-1 |

| ESRS 2|IRO-1 | iro-1-53-b | IRO-1 |

| ESRS 2|IRO-1 | iro-1-53-c | IRO-1 |

| ESRS 2|IRO-1 | iro-1-53-d | IRO-1 |

| ESRS 2|IRO-1 | iro-1-54 | IRO-1 |

| ESRS 2|IRO-2 | iro-2-56 | IRO-2 |

| ESRS 2|IRO-2 | iro-2-56-1 | IRO-2 |

| ESRS 2|IRO-2 | iro-2-57 | IRO-2 |

| ESRS 2|IRO-2 | iro-2-58 | IRO-2 |

| ESRS 2|IRO-2 | iro-2-59 | IRO-2 |

| E1-1 | E1-1-14 | E1-1 |

| E1-1 | E1-1-16-a | E1-1 |

| E1-1 | E1-1-16-b | E1-1 |

| E1-1 | E1-1-16-d | E1-1 |

| E1-1 | E1-1-16-h | E1-1 |

| E1-1 | E1-1-16-i | E1-1 |

| E1-1 | E1-1-16-j | E1-1 |

| E1-2 | E1-2-24-MDR-P-62 | E1-2 |

| E1-3 | E1-3-MDR-A | E1-3 |

| E1-3 | E1-3-MDR-A-69 | E1-3 |

| E1-4 | E1-4-34 | E1-4 |

| E1-5 | E1-5-38-a | E1-5 |

| E1-5 | E1-5-38-b | E1-5 |

| E1-5 | E1-5-38-c | E1-5 |

| E1-5 | E1-5-38-d | E1-5 |

| E1-5 | E1-5-38-e | E1-5 |

| E1-5 | E1-5-37-a | E1-5 |

| E1-5 | E1-5-AR-34 | E1-5 |

| E1-5 | E1-5-37-b | E1-5 |

| E1-5 | E1-5-AR-34-1 | E1-5 |

| E1-5 | E1-5-37-c-i | E1-5 |

| E1-5 | E1-5-37-c-ii | E1-5 |

| E1-5 | E1-5-37-c-iii | E1-5 |

| E1-5 | E1-5-37-c | E1-5 |

| E1-5 | E1-5-AR-34-2 | E1-5 |

| E1-5 | E1-5-37 | E1-5 |

| E1-5 | E1-5-39-1 | E1-5 |

| E1-6 | E1-6-47 | E1-6 |

| E1-6 | E1-6-AR-39-b | E1-6 |

| E1-6 | E1-6-AR-42-c | E1-6 |

| E1-6 | E1-6-AR-46-g | E1-6 |

| E1-6 | E1-6-AR-46-h | E1-6 |

| E1-6 | E1-6-AR-46-i | E1-6 |

| E1-6 | E1-6-AR-46-i-1 | E1-6 |

| E1-6 | E1-6-53 | E1-6 |

| E2-1 | E2-1-MDR-P | E2-1 |

| E2-1 | E2-1-MDR-P-62 | E2-1 |

| E2-2 | E2-2-MDR-A | E2-2 |

| E2-2 | E2-2-MDR-A-68-a-1 | E2-2 |

| E2-3 | E2-3-MDR-M | E2-3 |

| E2-3 | E2-3-MDR-T | E2-3 |

| E2-3 | E2-3-MDR-T-81-a | E2-3 |

| E2-3 | E2-3-MDR-T-81-b | E2-3 |

| E2-5 | E2-5-34 | E2-5 |

| E5-1 | E5-1-MDR-P-62 | E5-1 |

| E5-2 | E5-2-MDR-A | E5-2 |

| E5-2 | E5-2-MDR-A-69 | E5-2 |

| E5-3 | E5-3-MDR-M | E5-3 |

| E5-3 | E5-3-MDR-T | E5-3 |

| E5-3 | E5-3-MDR-T-81-b | E5-3 |

| E5-4 | E5-4-30 | E5-4 |

| E5-4 | E5-4-31-a | E5-4 |

| E5-4 | E5-4-31-b | E5-4 |

| E5-4 | E5-4-31-b-1 | E5-4 |

| E5-4 | E5-4-31-b-2 | E5-4 |

| E5-5 | E5-5-35 | E5-5 |

| E5-5 | E5-5-AR-27 | E5-5 |

| E5-5 | E5-5-36-c | E5-5 |

| E5-5 | E5-5-36-c-1 | E5-5 |

| E5-5 | E5-5-36-c-3 | E5-5 |

| E5-5 | E5-5-38-a | E5-5 |

| E5-5 | E5-5-38-b | E5-5 |

| E5-5 | E5-5-37-a | E5-5 |

| E5-5 | E5-5-37-b | E5-5 |

| E5-5 | E5-5-37-b-i | E5-5 |

| E5-5 | E5-5-37-b-ii | E5-5 |

| E5-5 | E5-5-37-b-iii | E5-5 |

| E5-5 | E5-5-37-c | E5-5 |

| E5-5 | E5-5-37-c-i | E5-5 |

| E5-5 | E5-5-37-c-ii | E5-5 |

| E5-5 | E5-5-37-c-iii | E5-5 |

| E5-5 | E5-5-37-d | E5-5 |

| S1-SBM-3 | s1-sbm-3-14 | S1-SBM-3 |

| S1-SBM-3 | s1-sbm-3-14-a | S1-SBM-3 |

| S1-SBM-3 | s1-sbm-3-15 | S1-SBM-3 |

| S1-SBM-3 | s1-sbm-3-14-c | S1-SBM-3 |

| S1-1 | S1-1-MDR-P-65-a | S1-1 |

| S1-1 | S1-1-MDR-P-65-b | S1-1 |

| S1-1 | S1-1-MDR-P-65-c | S1-1 |

| S1-1 | S1-1-MDR-P-65-d | S1-1 |

| S1-1 | S1-1-MDR-P-65-d-1 | S1-1 |

| S1-1 | S1-1-MDR-P-65-e | S1-1 |

| S1-1 | S1-1-MDR-P-65-e-1 | S1-1 |

| S1-1 | S1-1-MDR-P-65-f | S1-1 |

| S1-1 | S1-1-19 | S1-1 |

| S1-1 | S1-1-20-a-b-c | S1-1 |

| S1-1 | S1-1-21 | S1-1 |

| S1-1 | S1-1-21-1 | S1-1 |

| S1-1 | S1-1-22 | S1-1 |

| S1-1 | S1-1-23 | S1-1 |

| S1-1 | S1-1-24-a | S1-1 |

| S1-1 | S1-1-24-b | S1-1 |

| S1-1 | S1-1-24-c-1 | S1-1 |

| S1-1 | S1-1-24-d | S1-1 |

| S1-1 | S1-1-24-d-1 | S1-1 |

| S1-2 | S1-2-27 | S1-2 |

| S1-2 | S1-2-27-a | S1-2 |

| S1-2 | S1-2-27-b | S1-2 |